Click to email this to a friend (Opens in new window)

Could a DIY ultrasound be in your future? UBC breakthrough opens door to $100 ultrasound machine Science, Health & Technology

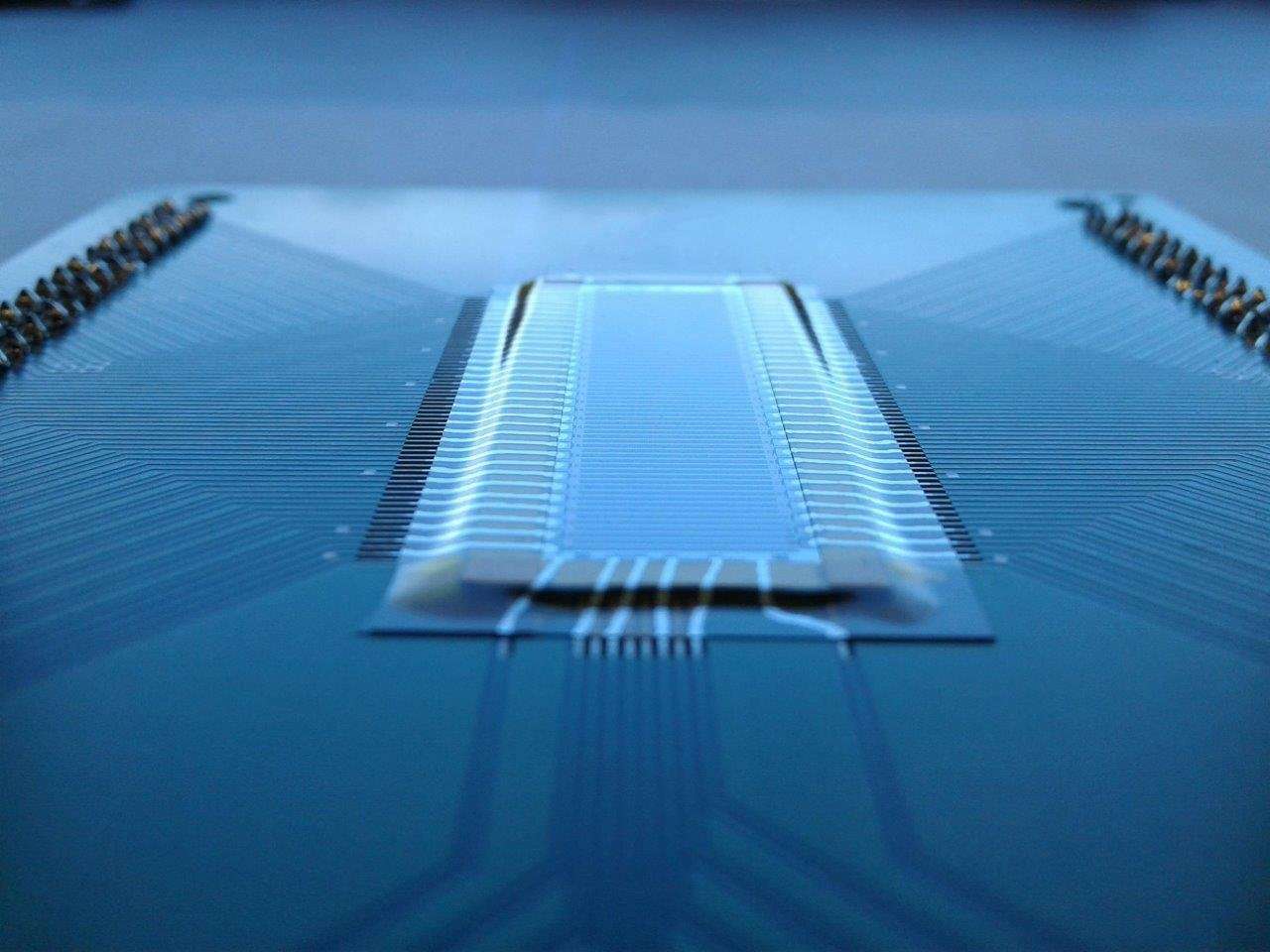

Engineers at the University of British Columbia have developed a new ultrasound transducer, or probe, that could dramatically lower the cost of ultrasound scanners to as little as $100. Their patent-pending innovation—no bigger than a Band-Aid—is portable, wearable and can be powered by a smartphone.

Conventional ultrasound scanners use piezoelectric crystals to create images of the inside of the body and send them to a computer to create sonograms. Researchers replaced the piezoelectric crystals with tiny vibrating drums made of polymer resin, called polyCMUTs (polymer capacitive micro-machined ultrasound transducers), which are cheaper to manufacture.

“Transducer drums have typically been made out of rigid silicon materials that require costly, environment-controlled manufacturing processes, and this has hampered their use in ultrasound,” said study lead author Carlos Gerardo, a PhD candidate in electrical and computer engineering at UBC. “By using polymer resin, we were able to produce polyCMUTs in fewer fabrication steps, using a minimum amount of equipment, resulting in significant cost savings.”

Sonograms produced by the UBC device were as sharp as or even more detailed than traditional sonograms produced by piezoelectric transducers, said co-author Edmond Cretu, professor of electrical and computer engineering.

“Since our transducer needs just 10 volts to operate, it can be powered by a smartphone, making it suitable for use in remote or low-power locations,” he added. “And unlike rigid ultrasound probes, our transducer has the potential to be built into a flexible material that can be wrapped around the body for easier scanning and more detailed views–without dramatically increasing costs.”

Co-author Robert Rohling, also a professor of electrical and computer engineering, said the next step in the research is to develop a wide range of prototypes and eventually test their device in clinical applications.

“You could miniaturize these transducers and use them to look inside your arteries and veins. You could stick them on your chest and do live continuous monitoring of your heart in your daily life. It opens up so many different possibilities,” said Rohling.

The research was published recently in Nature Microsystems & Nanoengineering.

Contact [email protected] to obtain a copy or to schedule interviews with the researchers.

PaleInTexas on September 12nd, 2018 at 02:27 UTC »

Ok so my wife is in the ultrasound industry and looked at this. Her first reaction is that it looks like it can replace the a probe.. not the whole machine which includes all the image controls, processing and hardware (basically a computer) interfacing with HIPAA compliant storage systems.

bones222222 on September 12nd, 2018 at 02:21 UTC »

An extremely similar non-piezo transducer already exists and has been fully implemented into a completed physical product: https://www.butterflynetwork.com/

Both are exciting developments and maybe differ very slightly, but I'm not sure about the IP on this one.

mvea on September 11st, 2018 at 21:02 UTC »

The title of the post is a copy and paste from the first paragraph of the linked academic press release here :

Journal Reference:

Carlos D. Gerardo, Edmond Cretu, Robert Rohling.

Fabrication and testing of polymer-based capacitive micromachined ultrasound transducers for medical imaging.

Microsystems & Nanoengineering, 2018; 4 (1)

DOI: 10.1038/s41378-018-0022-5

Link: https://www.nature.com/articles/s41378-018-0022-5

Abstract

The ultrasonic transducer industry is dominated by piezoelectric materials. As an emerging alternative, capacitive micromachined ultrasound transducers (CMUTs) offer wider bandwidth, better integration with electronics, and ease of fabricating large arrays. CMUTs have a sealed cavity between a fixed electrode and a suspended metalized membrane. Manufacturing cost and sensitivity are limiting factors in current CMUTs that depend on the fabrication equipment and, especially, on the materials used. For widespread use of CMUTs, a much lower fabrication cost that uses inexpensive materials, which maintain or improve upon existing sensitivity, is needed. Herein, a new fabrication process is described for polymer-based CMUTs (polyCMUTs) using the photopolymer SU-8 and Omnicoat. The first ultrasound B-mode image of a wire phantom created with a 64-element linear array using synthetic aperture beamforming techniques is presented. A 12 VAC signal superimposed on a 10 VDC signal was used on the transmission side, and only a bias-tee, with no amplifiers, was used on the receiving side. The low operational voltage and high sensitivity of this device can be partially attributed to a pre-biasing condition on the membrane. By using a novel sacrificial layer combined with a top electrode embedded inside the membrane, we demonstrated that SU-8 can be used to manufacture CMUTs inexpensively. Moreover, the fabrication used relatively simple equipment, and the number of fabrication steps was reduced compared to traditional CMUT fabrication. This new fabrication process has the potential to increase the use of CMUTs in the ultrasound market, including the market for wearable transducers.