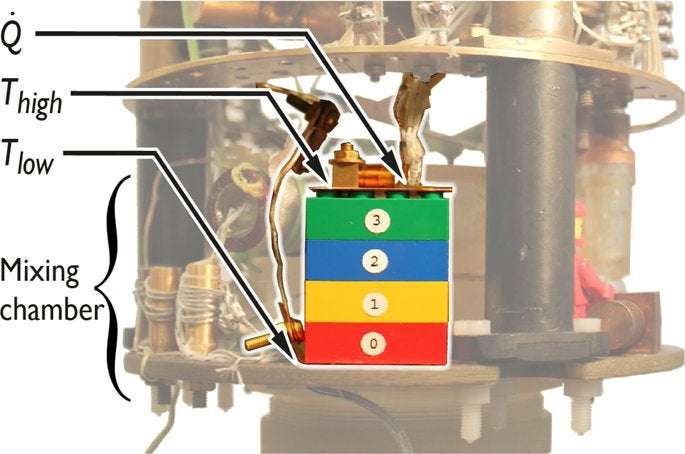

The experimental setup is shown in Fig. 1. We investigated a modular ABS structure comprising four standard LEGO blocks (Catalog No. 3001) stacked vertically and mounted in a Lancaster-built 3He/4He dilution refrigerator2. Since commercially available LEGO blocks are molded with a precision of σ x ≈ 10 μm3, it is very easy to reproduce structures accurately. The blocks were held together entirely by their interlocking geometry clamping power, with no added adhesive material. The stack had a total height Δx = 40.2 mm, a footprint area of a = 502 mm2 and weighed 9.28 g. Copper-plate connections on the upper and lower ends of the structure were attached with the aid of vacuum grease to improve the thermal contact4. The lower Cu plate was connected thermally to the mixing chamber of the dilution unit, and on the upper Cu plate a 3 Ω Manganin wire heater and a calibrated RuO 2 resistance thermometer were mounted.

Figure 1 Experimental setup. Heat \(\dot{Q}\) is applied via a 3 Ω manganin resistor and T high is measured with a RuO 2 resistance thermometer. Full size image

After cooldown, the lower plate was held at T low ≈ 4.5 mK for 9 days before the experiment was carried out. To measure the thermal conductance a constant heat level of \(\dot{Q}\) was applied to the upper plate. After the upper plate temperature T high stabilized a measurement was taken. A parasitic heat leak5 from the ABS structure (the slow leakage of heat from the ABS material itself) was measured to be \({\dot{Q}}_{0}=3.2\times {10}^{-10}\,{\rm{W}}\) (3.4 × 10−11 Wg−1), and was essentially constant over the time scale of the experiment.

For the thermal conductance of insulators at temperatures well below the Debye temperature, we can normally use the expression κ = λTn, where κ is the thermal conductance coefficient6. The constants λ and n can be determined by fitting the experimental data to the expression:

where T high and T low are respectively the high and low temperatures across the structure. This expression was obtained by integrating \(\dot{Q}/a=-\,\lambda {T}^{n}dT/dx\) over the height of the sample.

Since in all our measurements T high is much greater than T low , and n is found to be ~1.8, T low can thus be safely neglected.

The measured results for \(\dot{Q}\) versus T high for the modular ABS structure are presented in Fig. 2. A least squares fit to our experimental data for the longitudinal thermal conductance yields:

$$\kappa =(8.7\pm 0.3)\times {10}^{-5}\,{T}^{1.75\pm 0.02}\,[{{\rm{WK}}}^{-1}\,{{\rm{m}}}^{-1}].$$ (2)

Figure 2 Vertical temperature gradient across the modular ABS structure, dependent on heat load \(\dot{Q}\). A parasitic heat from the structure \({\dot{Q}}_{0}=3.2\times {10}^{-10}\,{\rm{W}}\) is added to our controlled heat \(\dot{Q}\). The full-line fit to the data yields n = 1.75 (see text). Full size image

Thermal conductances in plastic materials at very low temperatures in general show Tn dependencies with n ranging between 1.7 and 2.46, and our fit falls in this range. The thermal conductance of the extremely anisotropic modular ABS structure would clearly have a strong dependence on the axis of measurement.

Furthermore, and of importance in the current context, the modular ABS/void structure offers an order of magnitude lower thermal conductance than the best bulk thermal insulator, Macor1. The high level of insulation provided by the ABS structure most likely arises from the contact resistance between the individual LEGO blocks. As an illustration (taken from Fig. 1) the application of ≈400 nW of power to the top plate of the structure raises the top plate temperature to 1 K with no significant change in the bottom-plate (mixing chamber) temperature. For comparison, a Vespel-SP22 structure with the same footprint as the ABS modular structure would need to have a wall thickness of less than 300 μm to achieve the same insulation6. A “No 3001” LEGO block has a minimum wall thickness of 1.20 mm, and was found to withstand ≈300 kg of load in a hydraulic press before failing. This demonstrates that it is mechanically robust despite the void space and will sustain any reasonable cryogenic experiment.

The thermal contraction of the ABS on cooling from room temperature to 4.2 K is 1.5%7 versus 0.6% for Vespel SP-226. This could be important for certain applications, but for most applications, low thermal conductivity and cost are more important factors.

puzzleenthusiast on December 25th, 2019 at 12:28 UTC »

The author propose an explanation here:

Or in simple English, The LEGO has small contact area between blocks.

Lowgical on December 25th, 2019 at 09:38 UTC »

I know a few museum conservation departments use Lego to build support structures in objects because they are cheap, infinitely flexible, longer lasting and pretty stable chemically speaking.

heuristicbias on December 25th, 2019 at 06:48 UTC »

I wonder what prompted them to try Lego blocks in the first place...